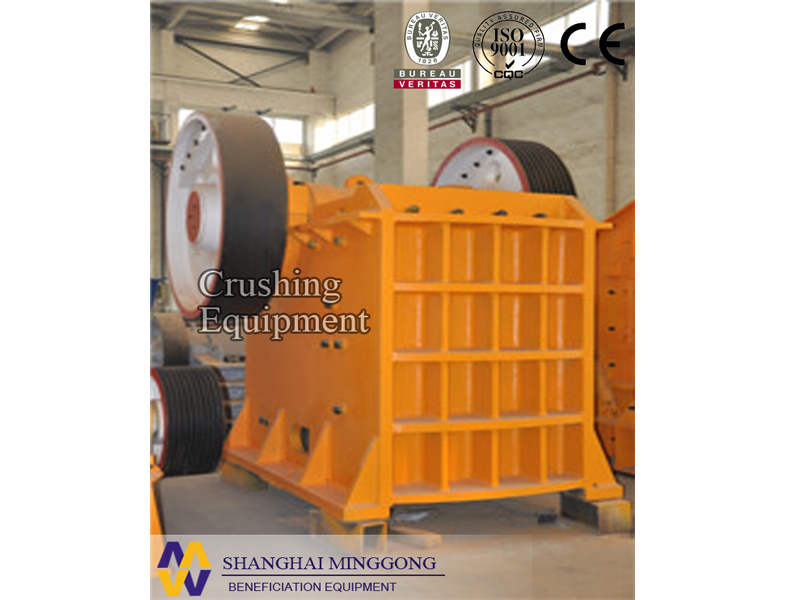

►Jaw Crusher(PE/PEX)Introduction:

At present, jaw crusher has become a very mature crushing equipments. It is mainly used in crushing various ores and big lumps into medium-size. Now it is widely applied in mining, smelting, building material, highway, railway, water conservancy and chemical industries. And it can crush the high hardness materials with 320Mpa compression strength.

PE jaw crusher has bigger feed size, it is suitable for rough crushing or primary crushing; PEX jaw crusher is mainly for a smaller feed size, and it has a smaller discharge opening, especially suitable for secondary crushing.

►Jaw crusher Features:

* Jaw crusher is stable performance; tenance;

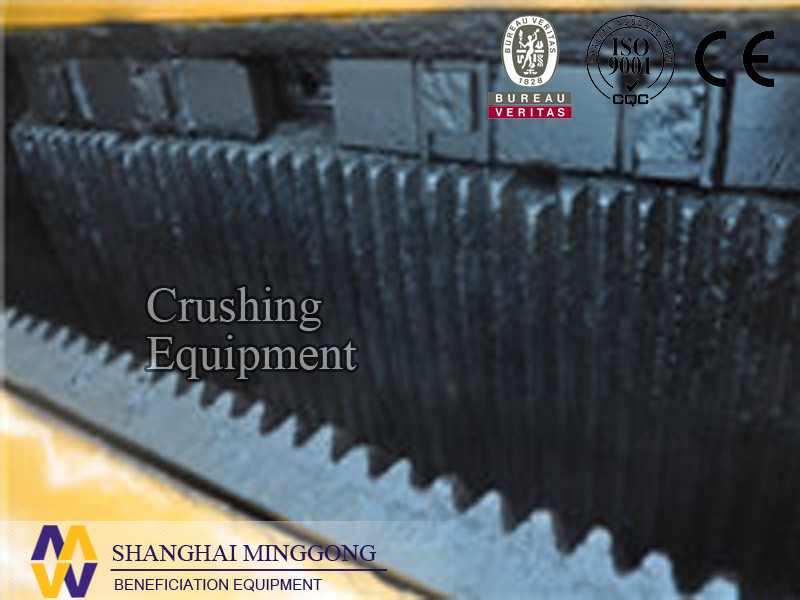

* Jaw crusher is even final particles and high crushing ratio* optimum structure for reliable quality;

* Easy access to wear areas for inspection and maintenance * Product size adjustable during operation;

* Efficient, non-choking operation;

* Higher crushing ratio; Lower power consumption;

It features in high broken ratio ,even rooduct size ,simple construction ,reliable operation ,easy maintenance ,and low consumption. It mainly applicable to various ores and big blocks’primary and secondary crushing.Advantages and characteristics:

1. Short toggle

2. Low hanging

3. Big swing angle

4. Long useful life

5. Easy maintenance

►Main Technical Parameters of Jaw Crusher :

| Model | Feed opening size (mm) |

Max feed size (mm) |

Adjustment range of outlet(mm) |

Capacity(t/h) | Motor power (kw) |

Weight (t) |

Overall dimension (L×W×H) (mm) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 5.5 | 0.8 | 720×660×850 |

| PE-250×400 | 400×250 | 210 | 20-60 | 5-20 | 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 600×400 | 340 | 40-100 | 16-60 | 30 | 7 | 1730× 1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-80 | 55 | 12.5 | 1980×2080×1870 |

| PE-600×900 | 900×600 | 500 | 65-140 | 50-150 | 75 | 17 | 2190×2206×2300 |

| PE-750×1060 | 1060×750 | 630 | 80-160 | 110-260 | 90 | 30 | 2660×2430×2800 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 110 | 52 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 150-265 | 220-550 | 110 | 54 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 190-300 | 400-800 | 160 | 100.9 | 4200×3300×3500 |

| PE-1500×1800 | 1500×1800 | 1100 | 220-350 | 450-900 | 355 | 123 | 5300×4700×4300 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 5-20 | 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 30 | 5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-50 | 37 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-65 | 37 | 8 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 20-90 | 55 | 12 | 2720×1950×1600 |

Please enter your demand such as Raw material type,Capacity, Feeding material size, Final product size. We will reply you as soon as possible.

E-mail: minggong@jxjq.com

E-mail: minggong@jxjq.com